Installation Guide for WPC Decking and Composite Decking by a Vietnam Manufacturer

Installation Guide for WPC Decking and Composite Decking by a Vietnam Manufacturer

I. Using WPC decking for your house construction is a good idea!

1.1. What is the WPC board?

WPC is an abbreviation for “wood plastic composite.” This material has numerous advantages because it is recyclable, environmentally friendly, and long-lasting. WPC consists of 50–55% wood powder, 30–35% plastics, and 10% additives, including coupling, lubricating, anti-UV, color-tagging, fire-retardant, and antioxidant agents. ? These elements are used to produce WPC composite outdoor decking boards. WPC composite decking has a natural look like real wood but resists weather changes much better. Therefore, composite decking can perfectly replace other types of wood decks.

☎️ You want to inquiry, contact Ms. Rivera:

✉️ Email: Rivera@europlastwood.com.vn

? Whatsapp/ Kakaotalk/ Line/ Telegram/ Zalo: (+84) 943 067 032

![]()

1.2. 5 Benefits of Using Wood-Polymer Composite Material in Outdoor Construction

Because WPC is anti-rot and anti-moisture, it will look and function better than general wood material for a longer period of time. While regular wood would bend or warp, wood-plastic composites can withstand heat much better than regular wood.

1.2.1. Low maintenance

1.2.2. Safe for children

1.2.3. Durable and strong

1.2.4. environmentally friendly

1.2.5. Low cost

II. Installation guide for WPC decking from a Vietnam manufacturer

If you want to design your garden and outdoor area beautifully and get closer to nature, what about decorating your flooring with WPC decking?

2.1. Some preparations before installing WPC decking

1. Preparation accessories

Make sure you fully prepare the following accessories before starting construction:

- Decking

- Joist

- Decking

- Stainless steel screw, 25mm

- PLastic Clip

- Stainless steel screw, 35mm

- Edge caps

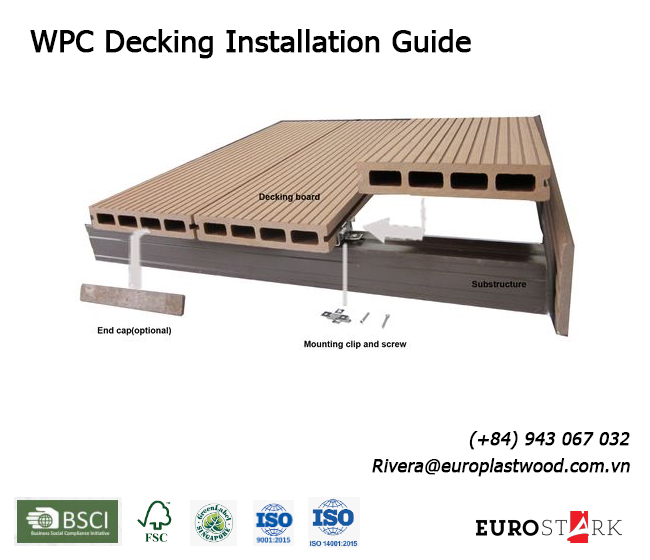

Here are pictures of these accessories for your better imagination and preparation. ❤️❤️❤️

2. Prepare the required tools.

- Tape measure

- Hammer

- Circular saw

- Stopper rails

- Hammer drill

- Rechargeable screwdriver

- Sprit level

3. Safety Instructions

Don’t rush! Please read this carefully before starting. ?

- Wear safety glasses, ear protectors, and safety gloves, and ensure there is adequate ventilation.

- When cutting and installing, keep onlookers, especially children and pets, at a safe distance.

- Do not expose the finished decking to hard, heavy, or sharp objects, knocks, or blows.

- Never drive a vehicle on the decking.

4. Description

Maintenance-free composite decking without knots consists of 58% wood, 32% HDPE, and 10% additives in the form of UV protection and reinforcement.

Supplement with edge boards of composite material, end caps, start clips, metal clips, and plastic clips, all specially adapted for this decking.

5. Planning notes

The sub-construction may be laid on even cement surfaces or cement panels on a bed of chipped stones. The thickness of the cement panel must be at least 6 cm.

For patios and balconies with tarmac surfaces, the surfaces may not be damaged during installation.

Place floor boards in areas with moderate sunlight and balanced, moderate temperatures to avoid mold formation and floor board distortion.

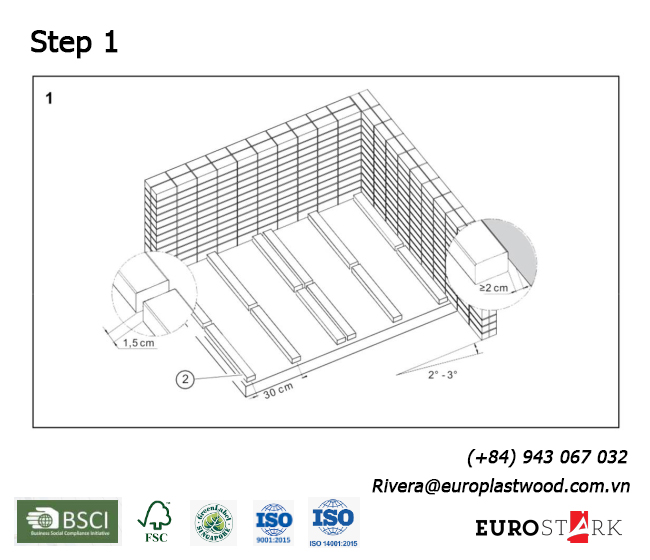

Allow at least 2 cm of space on all sides of all walls, balcony railings, and other permanently installed objects.

Excessive static loads (high terrace) must not be applied to the material. – Ensure adequate water drainage (at least a 2-3% slope) and ventilation.Do not lay on surfaces that store water.

Avoid moisture accumulation. Drainage may need to be laid; avoid contact with the earth.

Do not fill cavities; this ensures ventilation underneath.

Observe the minimum distances for the expansion joints.

WPC floor boards may bleach with sunlight by up to 10%.

In strong sunlight, WPC floor boards may heat up.

It is recommended to use the corrugated side of the boards as the top. The smooth side may become slippery thanks to moss.

6. Preparation

Before installation, remove any product stickers. Any discoloration will disappear after a short time.

Prior to laying, create a laying plan to reduce waste produced by cutting.

The boards may display deviations in color. Mix the boards before laying.

Pre-cut the boards to the appropriate size and chamfer the edges.

During installation, the outdoor temperature should be 10–30 degrees Celsius.

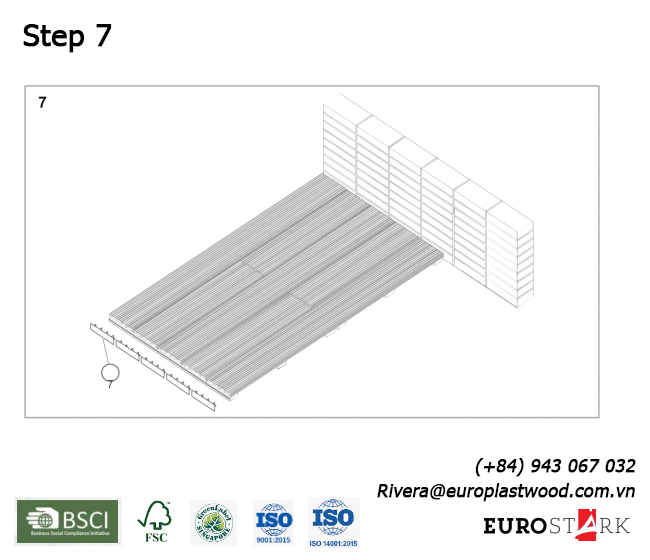

2.2. After getting everything ready, let’s install your WPC decking! ?

The composite boards should be mounted on an underlying surface with good drainage and circulation of air, where water does not accumulate.

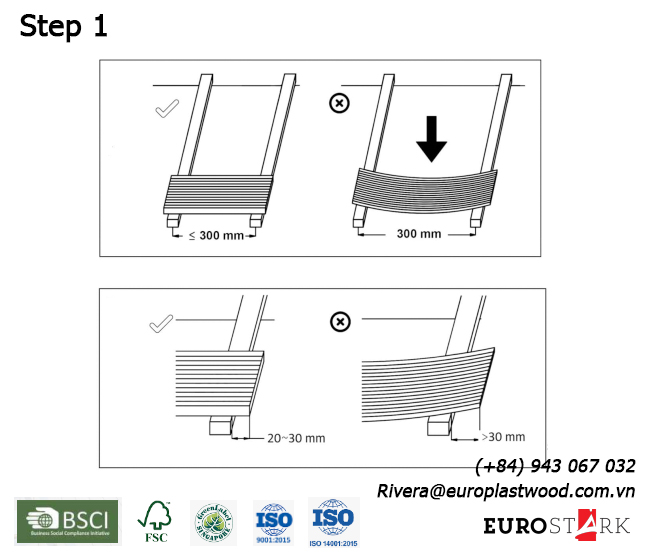

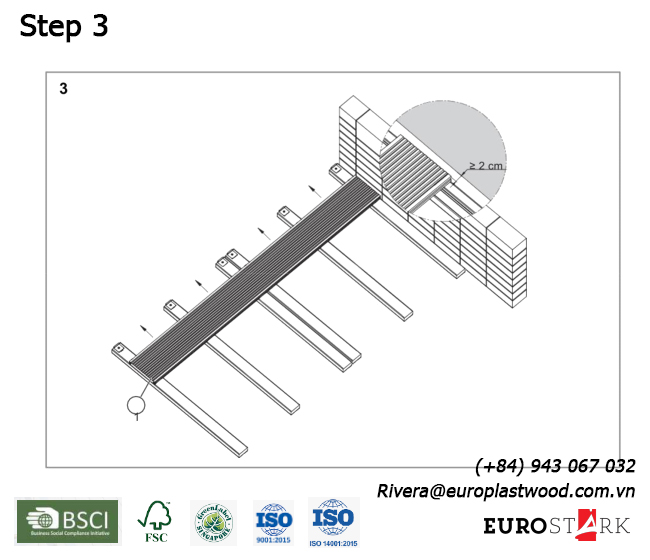

- The maximum distance between joists is 30 cm. The gap between the joist and the wall is at least 2 cm.

- The composite boards can be laid with an optional side up, grooved, or embossed.

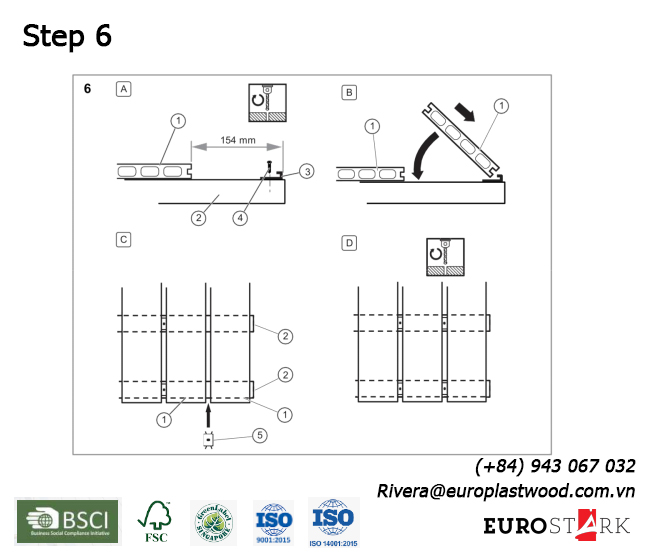

- Screw on the end clips along the outer long sides of the decking. Lay the boards in place and align their longitudinal grooves with the end clips.

- Both ends of the boards must rest on a stud and not protrude by more than 20 to 30 millimeters at the end of the decking.

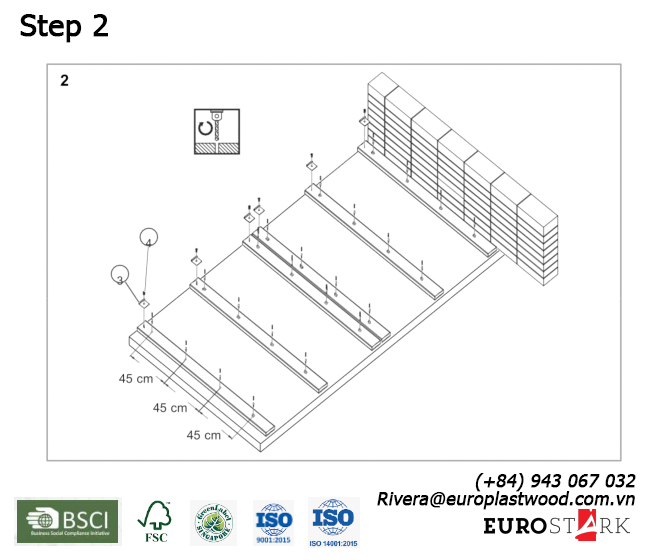

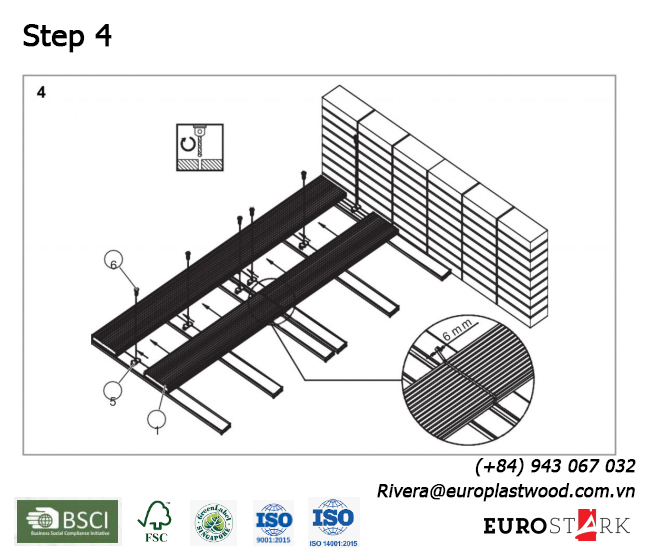

- The maximum distance between screws on a joist should be 45 cm.

- Mark the position of the starter clips on the substructure and pilot drill. The clips must be mounted precisely in a straight line. Screw the starter clips into place.

- Slide the first board into the starter clips.

- Leave a gap of at least 2 cm on all sides of any wall, balcony railings, or other permanently installed objects

- Slide the connecting clips for the next boards, mark the position, and pilot drill.

- Screw the connecting clips into place, but not firmly.

- Using a spacer, slide the boards in.

- Mount additional boards using connecting clips.

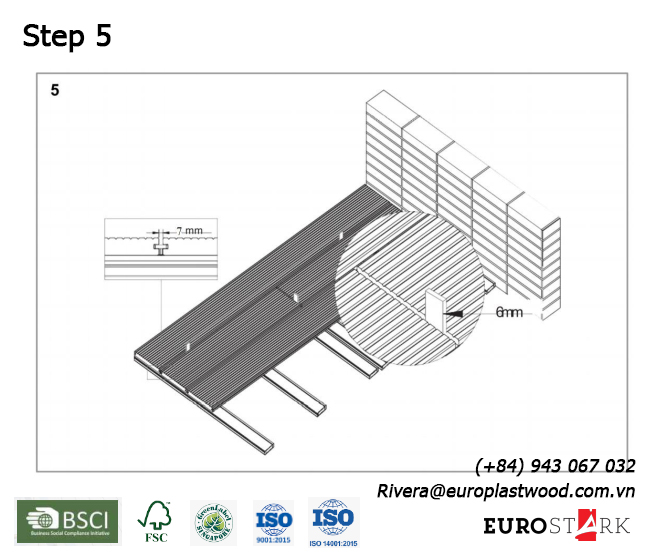

- Leave a gap of 6-7 mm for the boards to expand. Use suitable blocks to measure the gap.

- Install the final board with starter clips.

- After completing the laying process, screw all connecting clips firmly into place.

- Cut the head ends to a uniform length. Use a handheld circular saw with a stopper rail.

- Glue the end caps with flex glue to the ends of the boards.

*** Care Notes for WPC Boards ?

All materials used outdoors require care.

In order to maintain the original appearance, clean the flooring after laying it and treat it with a suitable WPC cleaning or care product.

Cleaning can be carried out with water or with soapy water, depending on the level of contamination.

This treatment must be repeated approximately every six months. In the event of aggressive conditions, it may be necessary to treat more often.

Disposing of the packaging

The packaging consists of cardboard and marked plastics that can be recycled.

Take these materials to a recycling center.

WATCH VIDEO FOR BETTER INSTRUCTION

III. WPC Decking Produced by a Vietnamese Manufacturer: ISO 14001:2005, ISO 9001:2015, FSC, Green Label

3.1. A short introduction about our WPC factory and company

We are EUROSTARK, a wood-plastic composite manufacturer in Vietnam. We’ve been exporting internationally since 2015.Our target markets are the EU, US, Canada, Korea, Japan, etc. Our company is one of the leading OEM manufacturers in the WPC decking industry in Southeast Asia.

The benefits of WPC decking include high quality, low maintenance, low cost, durability, high fashion, and environmental friendliness.All of these benefits will definitely satisfy even the strictest customers from developed countries. Since 2015, we have put a foot in Germany, North America, the Middle East, and Korea with over 200 containers per year.

3.2. Our products are fully certified to international standards.

With a view to making all customers happy, we already have full international certificates. Our certificates include BSCI meet, FSC, Green Label, EN15534, ISO 14001:2005, and ISO 9001:2015. Moreover, our WPC products have also passed quality tests, namely the Intertek test, the UV test, the color test, etc. We invest in and develop the R&D laboratory with cu-ting edge testing machines to make sure our products’ standard.

IV. CONTACT US FOR MORE DETAILS

Thank you very much for considering our WPC products, and we are willing to support and supply you. EUROSTARK is the leading brand of wood-plastic composite not only in Vietnam, but also throughout South East Asia.Your satisfaction is our happiness. We are confident in our ability to provide you with consistent quality, on-time delivery, and a knowledgeable and professional working environment.

☎️ You want to inquiry, contact Ms. Rivera:

✉️ Email: Rivera@europlastwood.com.vn

? Whatsapp/ Kakaotalk/ Line/ Telegram/ Zalo: (+84) 943 067 032

plastic composite decking

decking

garden deck

decking bearers

deck boards

flooring

pergola

cladding

composite decking

deck tiles

Wood Plastic

DIY Floating Deck

DIY deck

floating deck

balcony flooring

#compositedecking

#installdecking

#outdoorflooring

#compositedeckinginstallation

#outdoordecking

#wpc

#wpcdecking

#wpcmanufacturer